A leading fabricator of specialised Architectural Metalwork in the UK, operating the latest state-of-the-art manufacturing equipment, allowing a highly skilled workforce to deliver precision fabrications in a wide range of materials for the architectural, building and construction sector.

As an award-winning facade specialist, Metalline is dedicated to being industry leaders in innovation and testing. They rigorously test all their panel ranges for Impact Resistance, Wind Resistance, and Fire Performance, setting the standard for safety and reliability in architectural metalwork solutions.

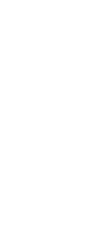

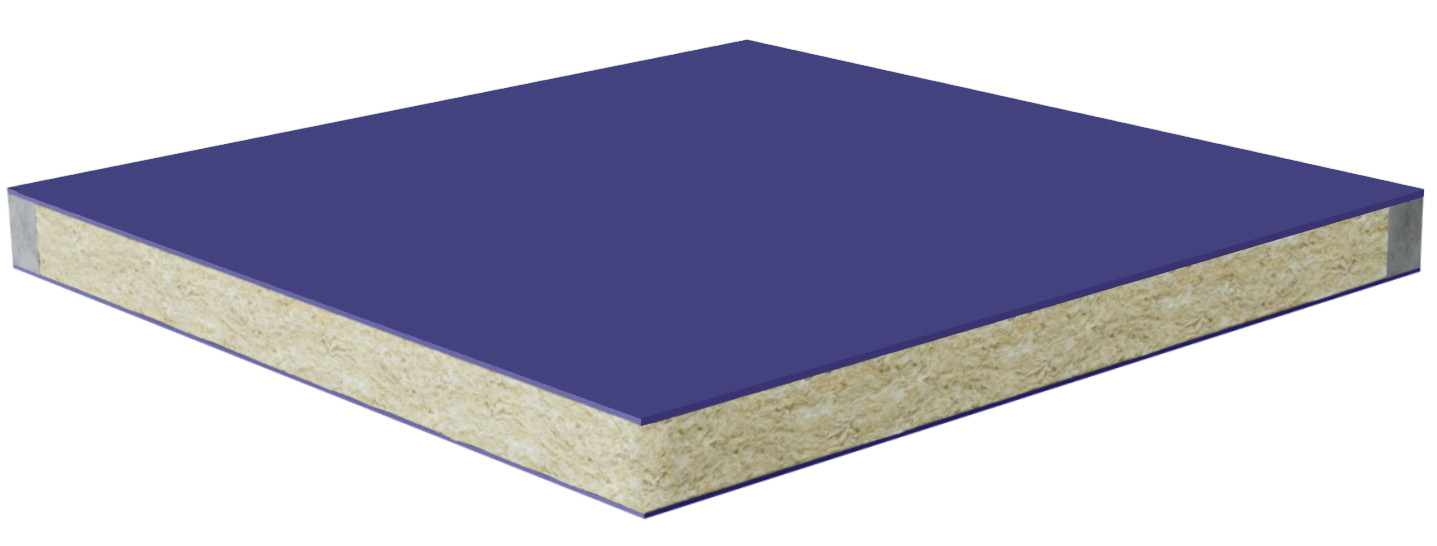

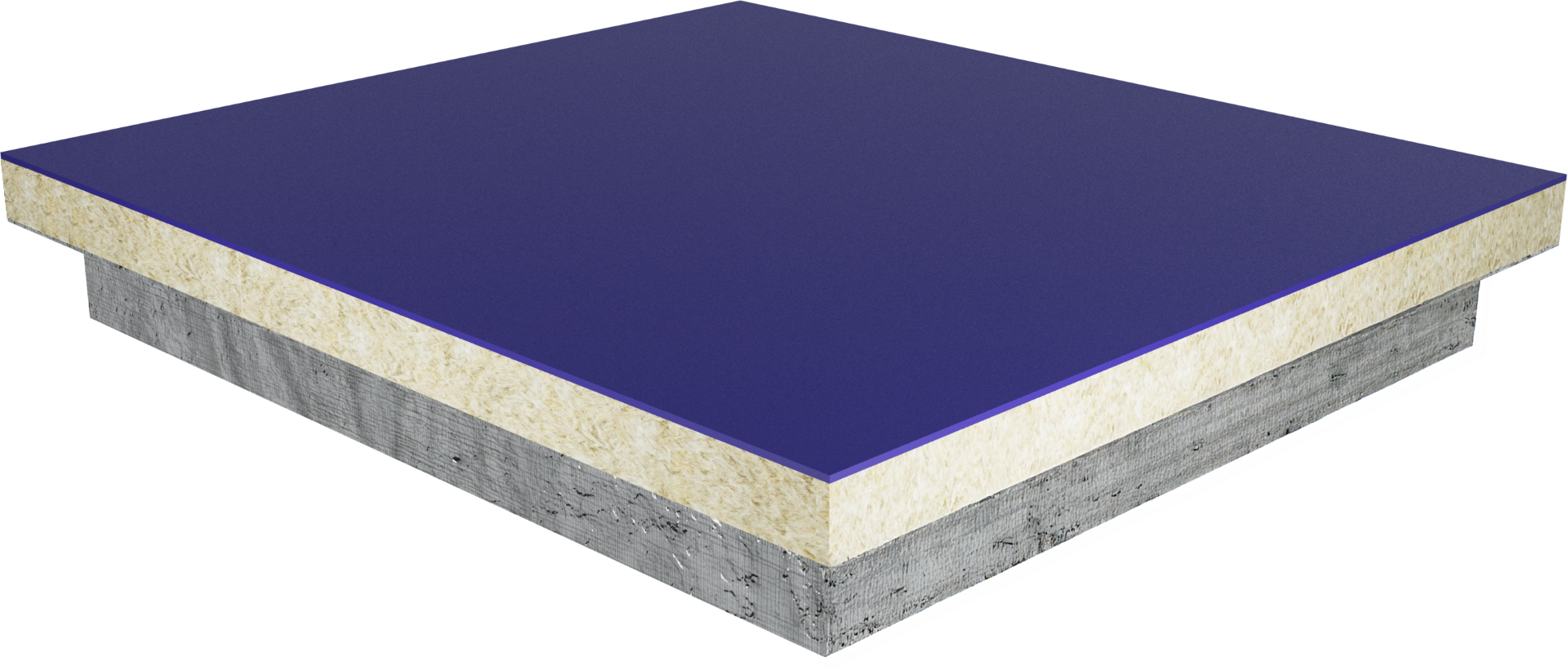

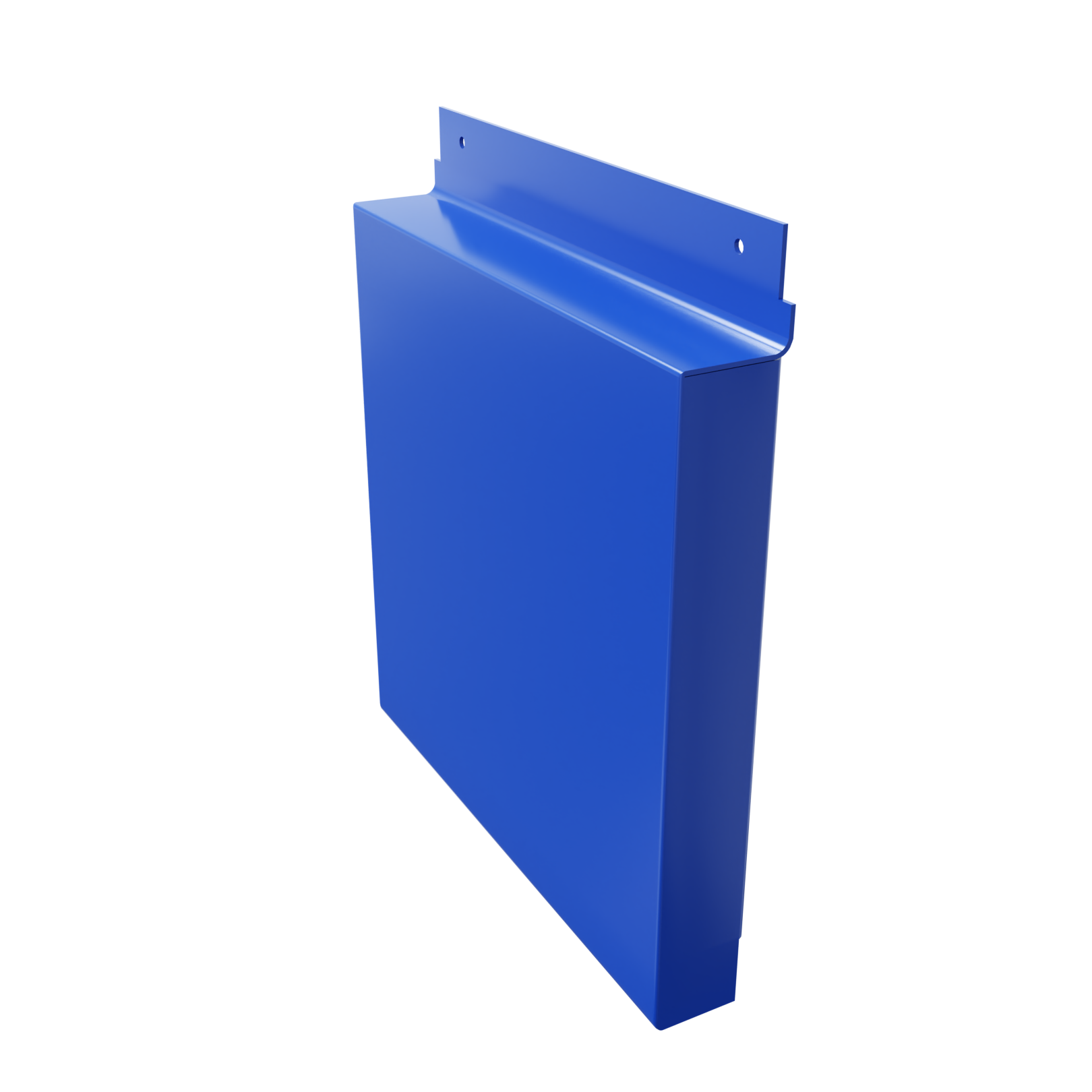

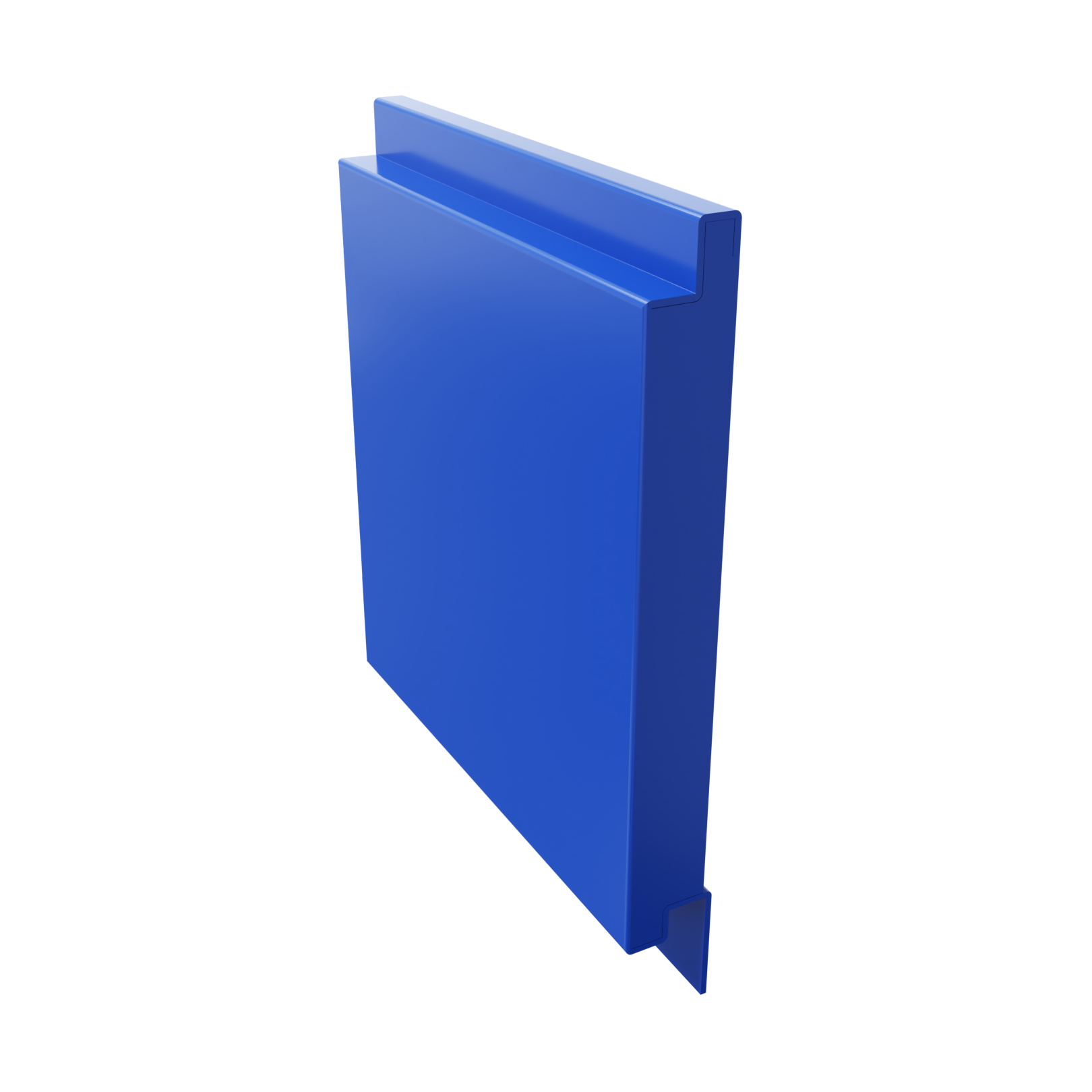

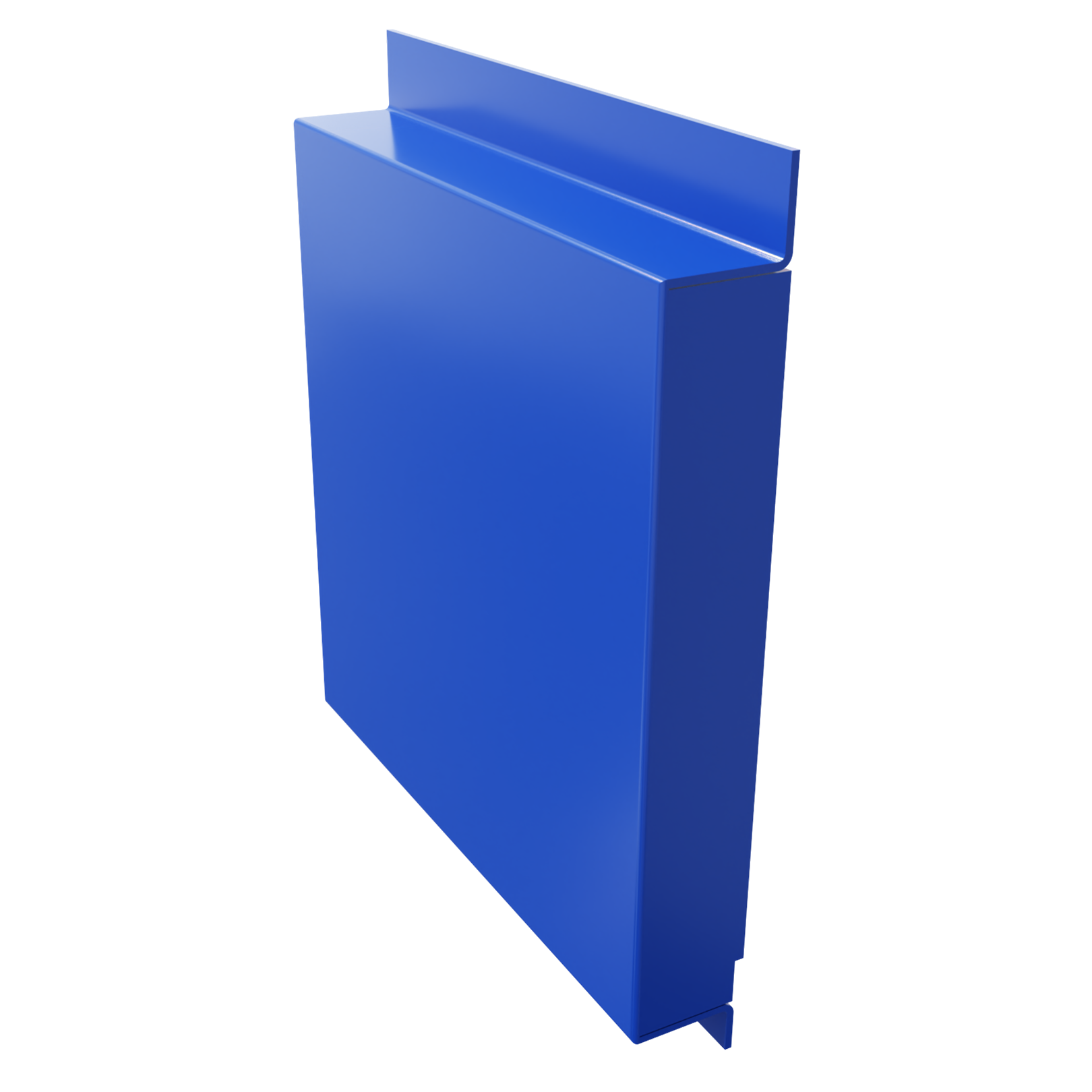

ULTIMA 1 is an insulated spandrel panel crafted for adaptability, featuring a range of finishes to align with project specifications. The external layer boasts an aluminium tray available in anodised or PPC finish, adding a sleek and customisable aesthetic. The core is constructed with Fabrock Clad insulation, ensuring optimal thermal performance and flexibility in achieving desired ‘U’ values.

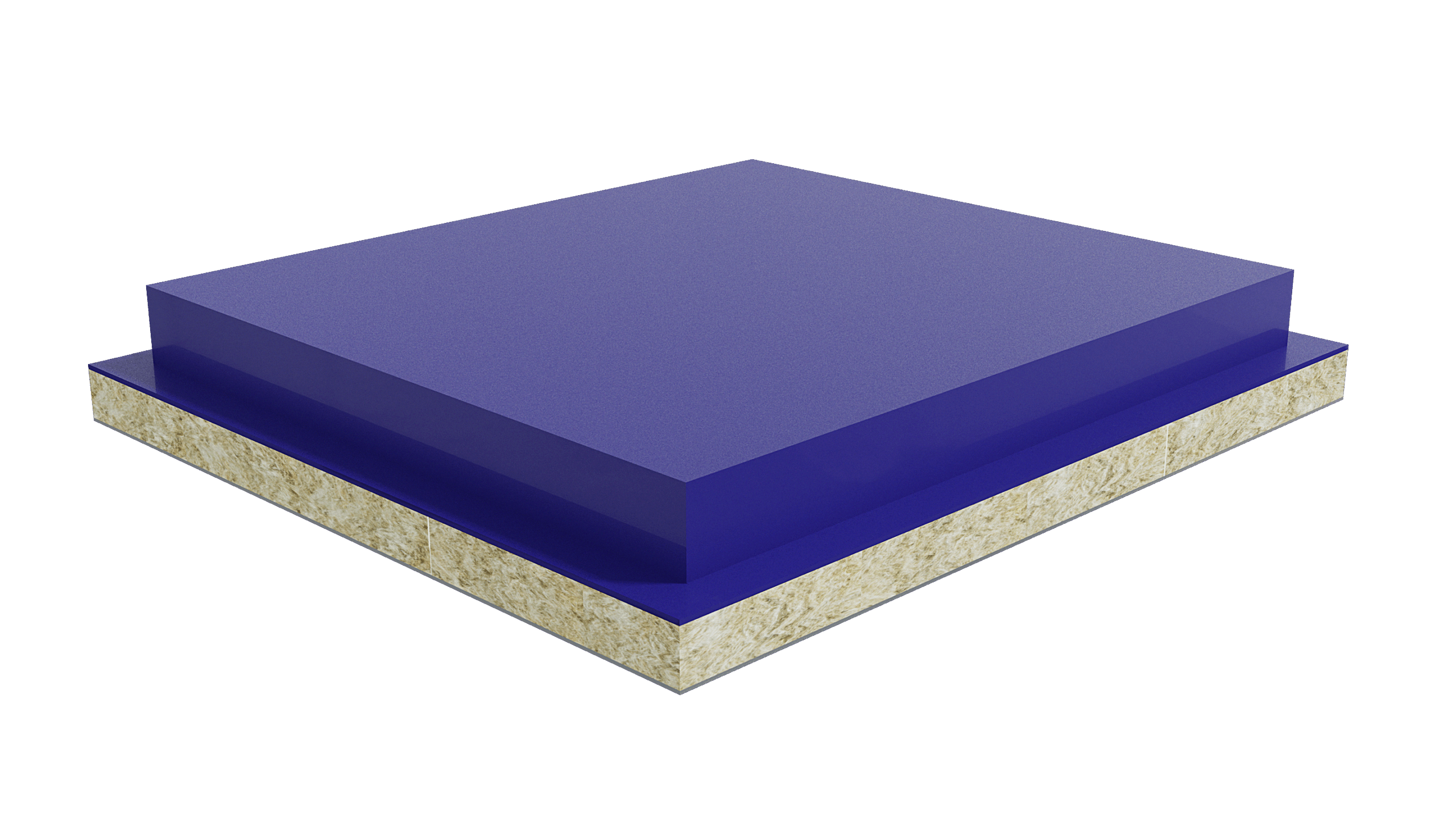

ULTIMA 2, part of Metalline’s Insulated Spandrel Panel range, has achieved A1 and A2 – s1, d0 classifications according to BS EN13501-1, making it an ideal choice for new builds or replacing non-compliant Spandrel Panels. With limitless colour options, low maintenance requirements, and robust construction, ULTIMA 2 offers a cost-effective and aesthetically customisable solution.

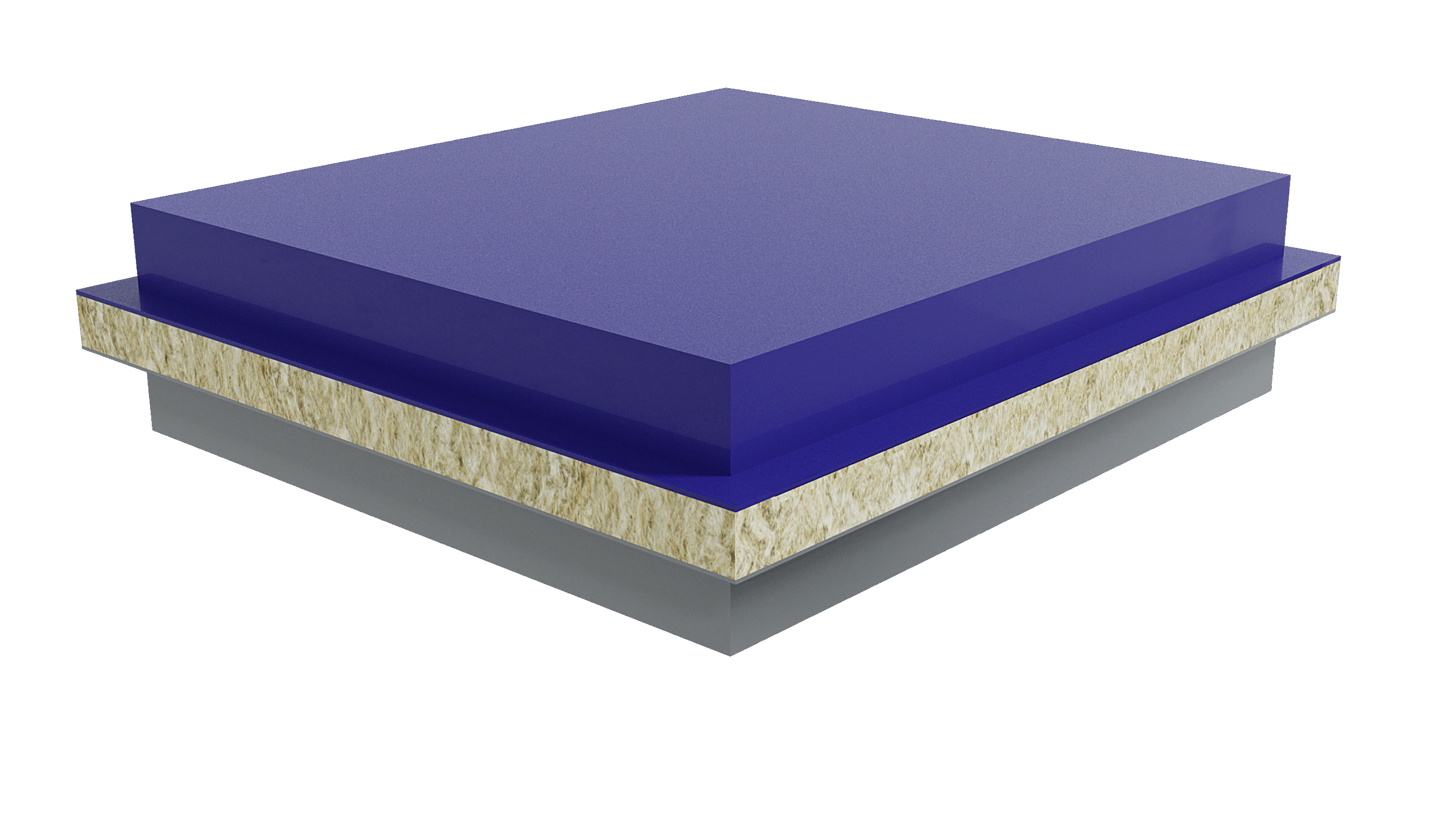

The ULTIMA 3 Insulated Spandrel Panel offers versatile finishes, allowing customisation based on classification requirements. The insulation thickness can be adjusted for desired ‘U’ values in your project. Externally, it features an aluminium tray with an anodised finish. The core comprises Fabrock Clad insulation, while internally, foil-faced Rockwool insulation is fitted to a galvanised steel/aluminium balancer sheet.

ULTIMA 4, part of Metalline’s Insulated Spandrel Panel range, has undergone rigorous testing to BS EN13501-1, achieving both A1 and A2 – s1, d0 classifications. This makes it an excellent choice for new construction projects or replacing non-compliant Spandrel Panels. The external layer features an aluminium tray with the option of an anodised or PPC finish, providing a sleek and customizable exterior.

ULTIMA 5, a part of the ULTIMA Insulated Spandrel Panel series, offers a versatile solution with customisable face finishes to match the required classification. The insulation thickness is adjustable to accommodate specific ‘U’ values for your project, making it a flexible choice. Featuring an external layer with an aluminium tray and anodised finish, ULTIMA 5 ensures a sleek and modern appearance.

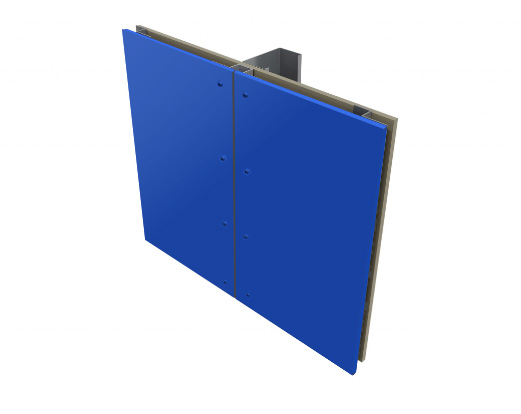

A face fixed non-combustible solid aluminium rainscreen panel that is perfect for the replacement of existing HPL and ACM cladding panels.

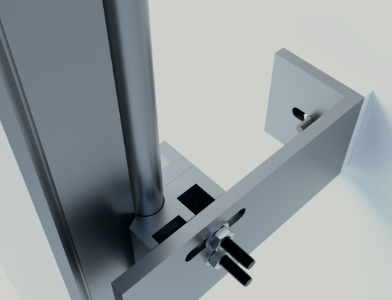

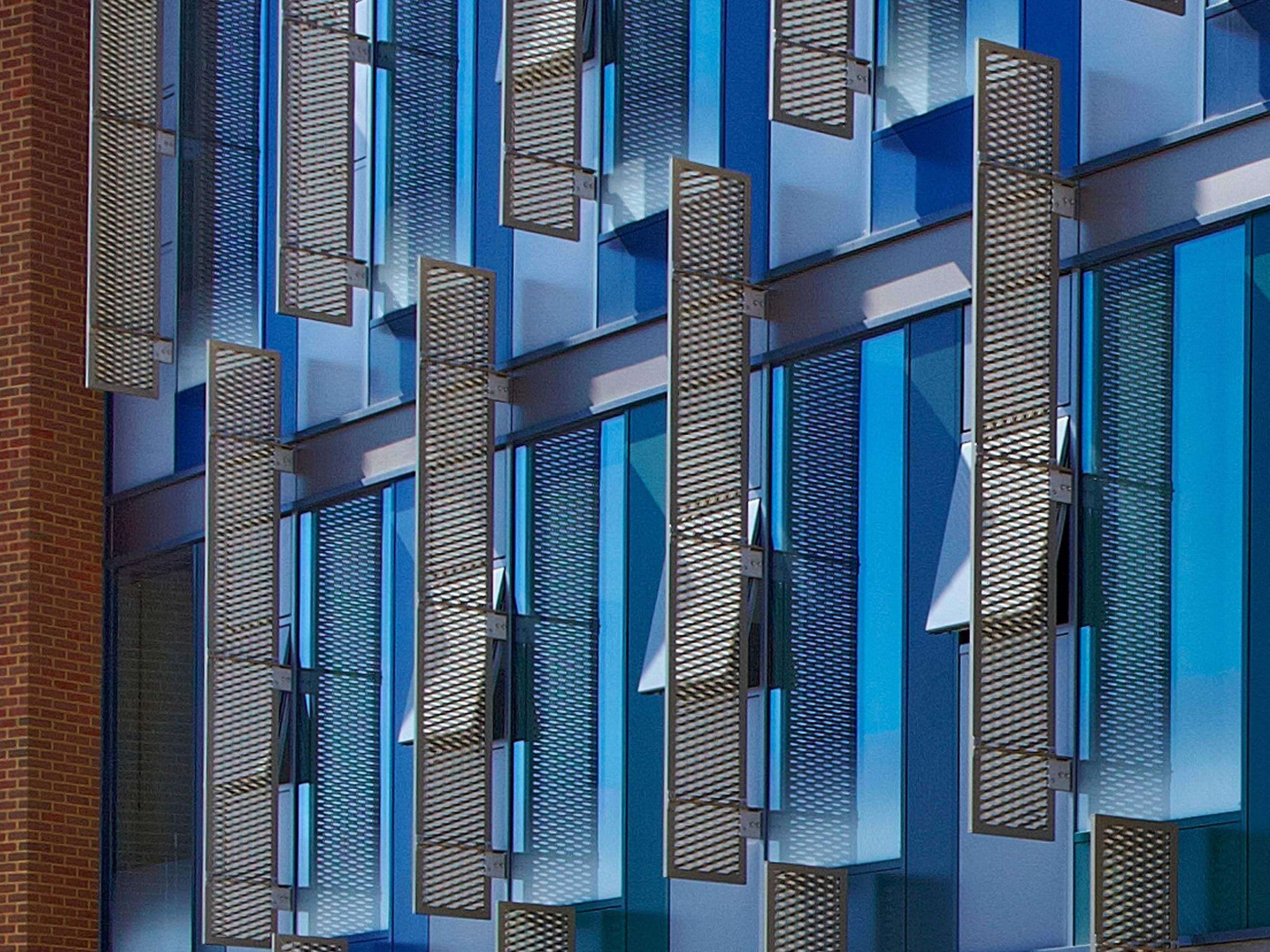

A non-combustible “Hook-On” secret fix cassette system which provides a streamlined appearance whilst remaining quick and easy to install.

A non-combustible interlocking pressed plank which can be used as either a cladding panel or soffit system.

A versatile non-combustible rainscreen cassette system available in both landscape and portrait orientation. Colour matched fixings located in the recessed shadow joint provide a streamlined aesthetic.

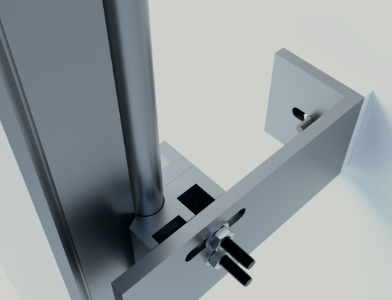

The UNITY F2F framing system has been designed to accommodate, flat, discrete-fix and hook-on rainscreen panels and is fully compliant with all types of A1 and A2 facade panels including aluminium, Rockpanel, fibre cement, ACM and terracotta.

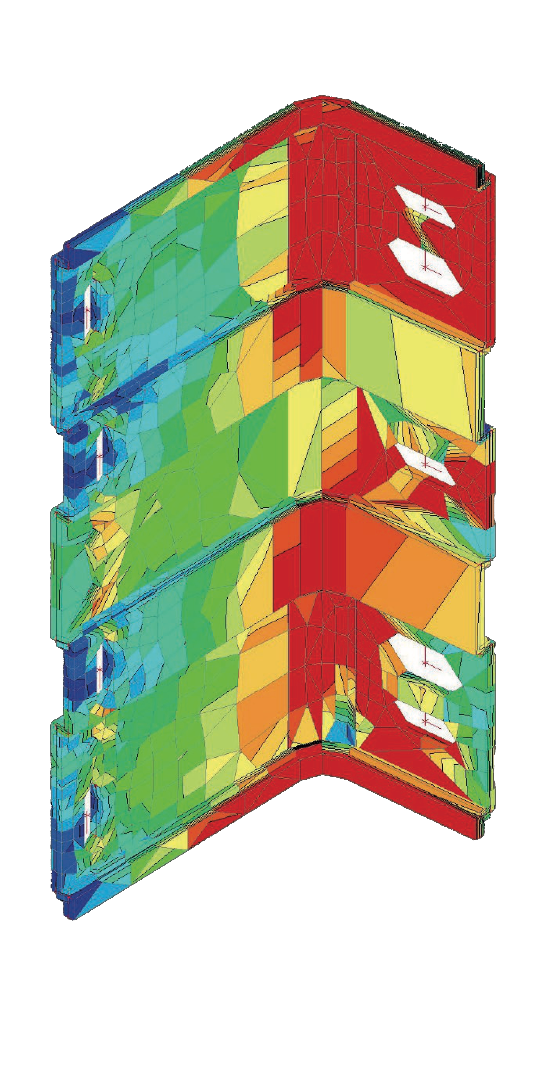

Façade Engine is a state-of-the-art analysis tool which provides comprehensive static calculations to help generate the optimum framing design.

Click to register for our free to use software

CLAD-LINE is one of the UK’s leading manufacturers of extruded aluminium non-combustible subframe systems. With over 35 years of experience in the manufacture and supply of rainscreen systems, CLAD-LINE have developed a complete set of framing solutions.

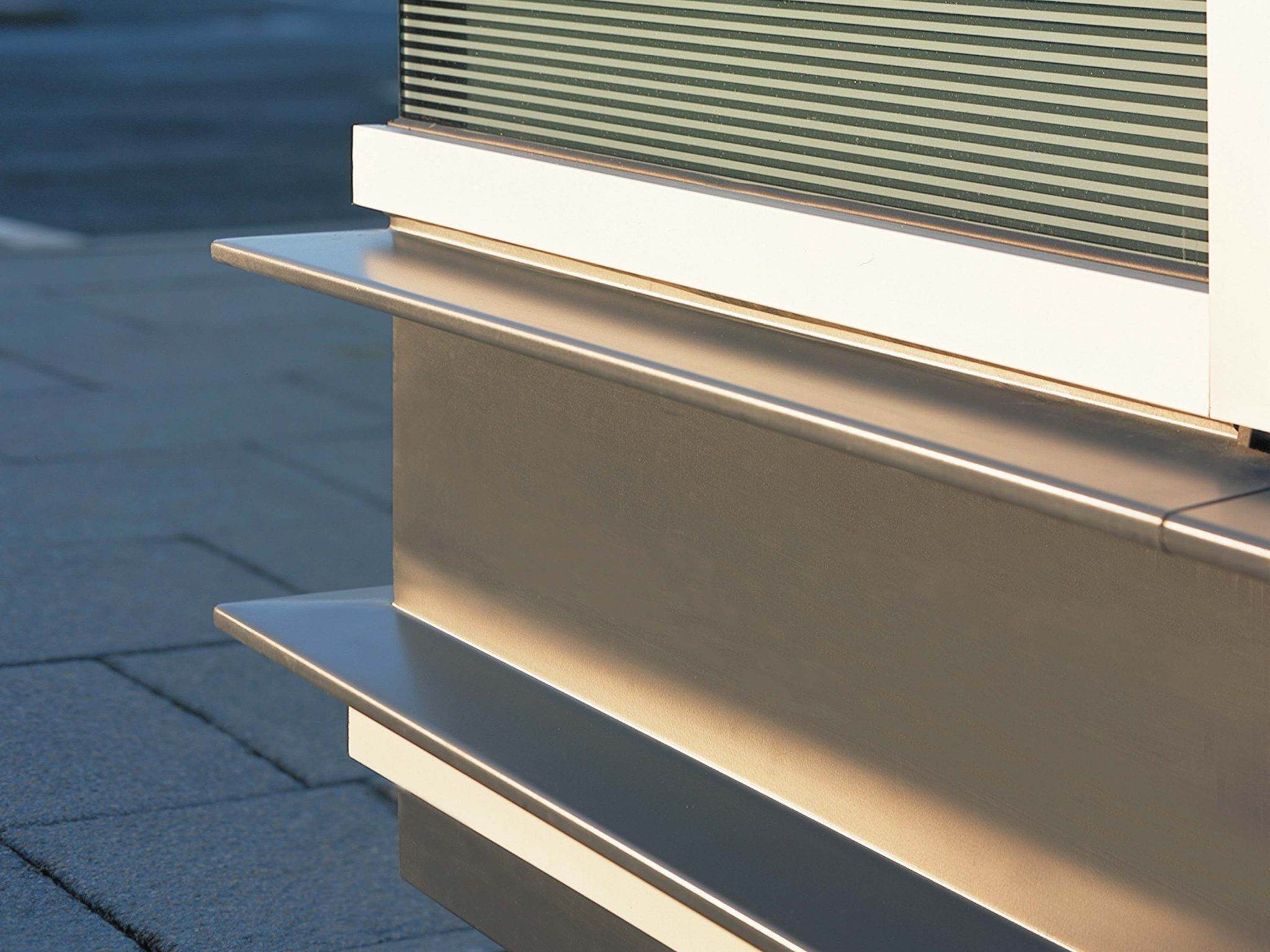

Metalline have been producing a wide range of architectural aluminium pressings for over 20 years and have extensive experience in producing bespoke products to your exact specification.

Feature Beam, the alternative to a structural I-beam, is a highly adaptable metal pressing which will enhance the appearance of any building façade. Metalline’s continuous investment into innovative manufacturing processes has led to the development of pioneering architectural products. Feature Beam, the decorative alternative to a structural I-beam, can be used in conjunction with most curtain walling and cladding systems to provide a unique exterior finish to any building.

Metalline (Services) Ltd,

Hollies Park Road,

Cannock,

Staffordshire,

WS11 1DB